As another year comes to a close and we get ready for the year to follow, let’s look back on the highlights from 2023.

Projects

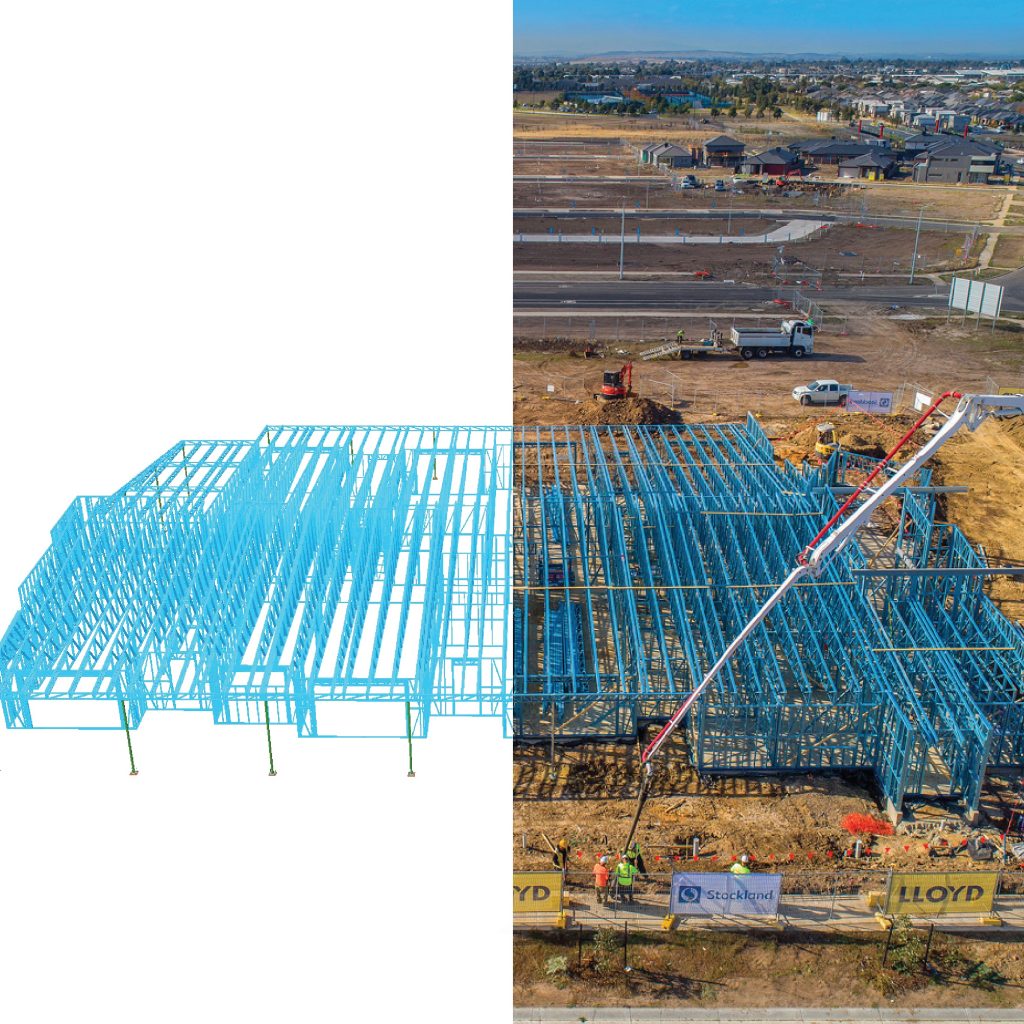

This past year we have yet again completed a wide array of projects. From large townhouse developments through to high-end residential and commercial builds.

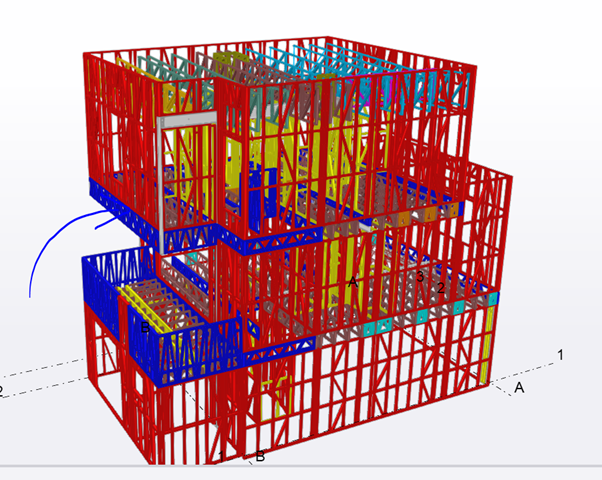

Some of the townhouse developments completed include

- Doveton Ave, Eumemmering -28 townhouse development

- Kororoit Creek Rd, Williamstown – 67 townhouse development

- Waterline Place, Williamstown – 14 townhouse development

- Alvina Street, Oakleigh South – 96 townhouse development

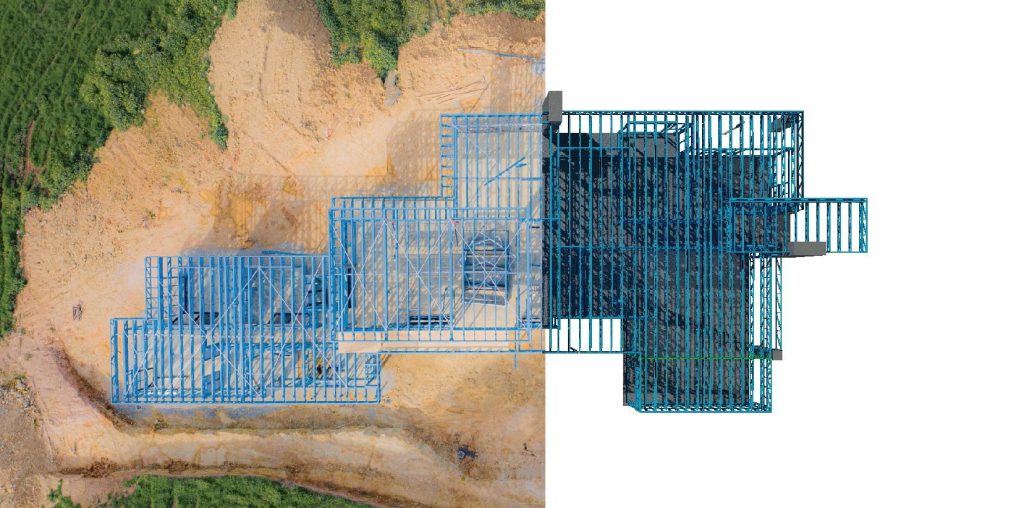

Project Bordeaux

Dynamic Steel frame provided both light gauge and structural steel for Project Bordeaux by Elation Homes. A high-end build on Neville street, Bentleigh.

This build showcases the advantages of using light gauge steel in high-end projects, specifically referring to the undeniably straight walls, magnificent curved details and large open spaces.

Latest Innovation

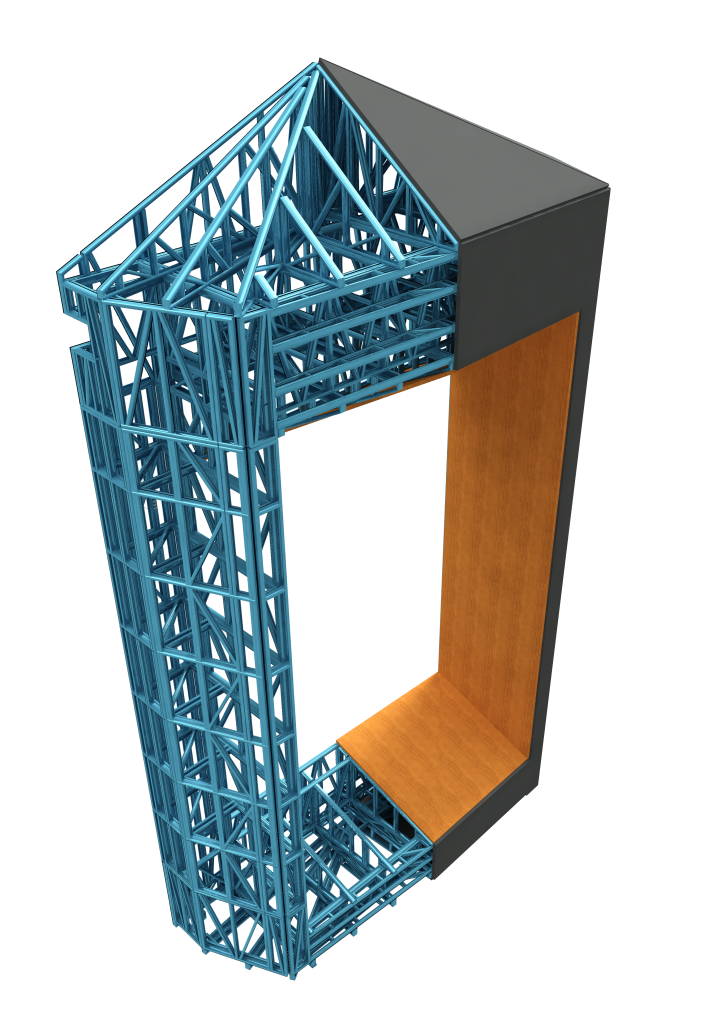

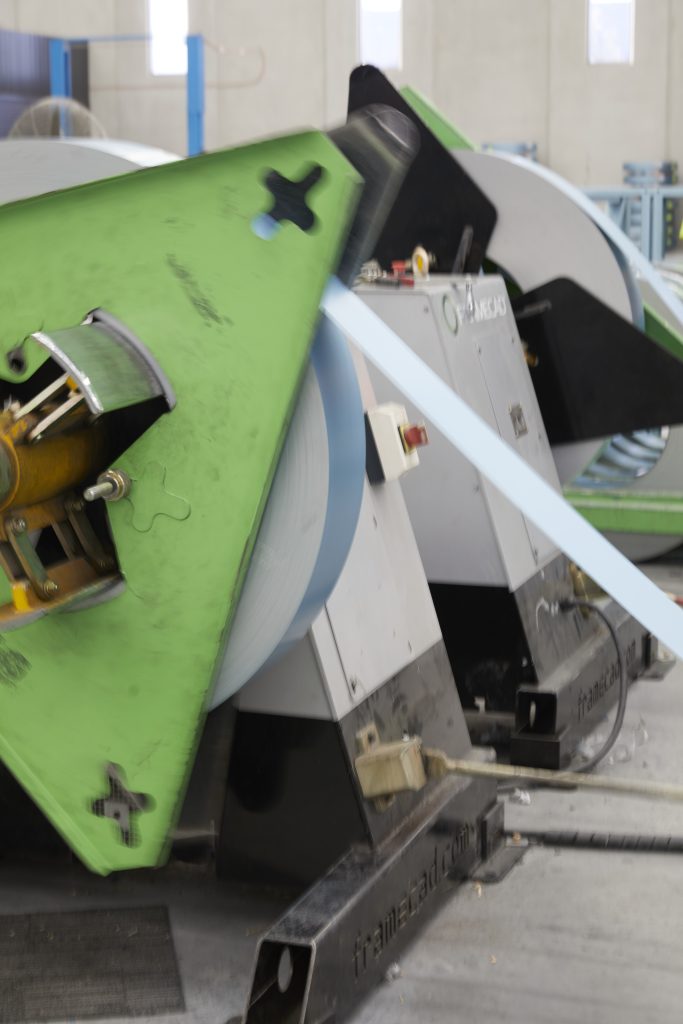

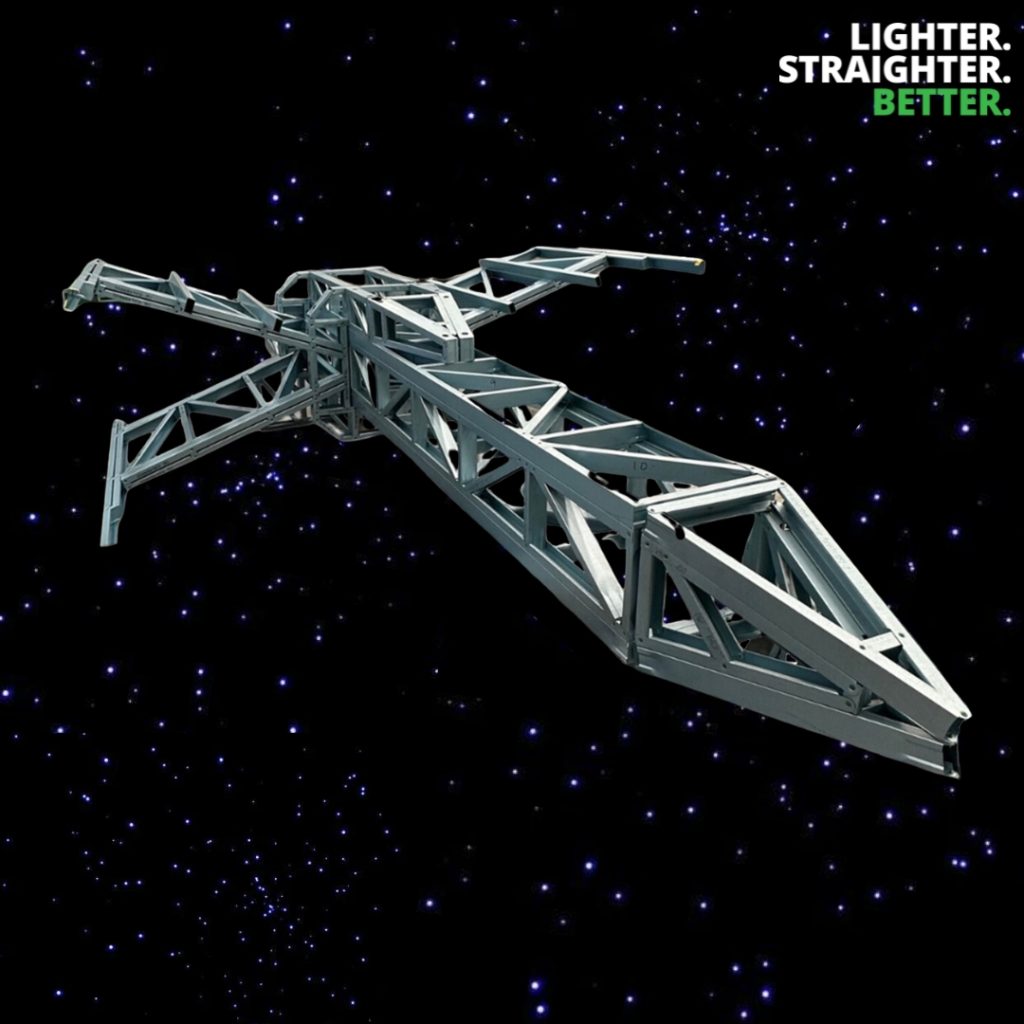

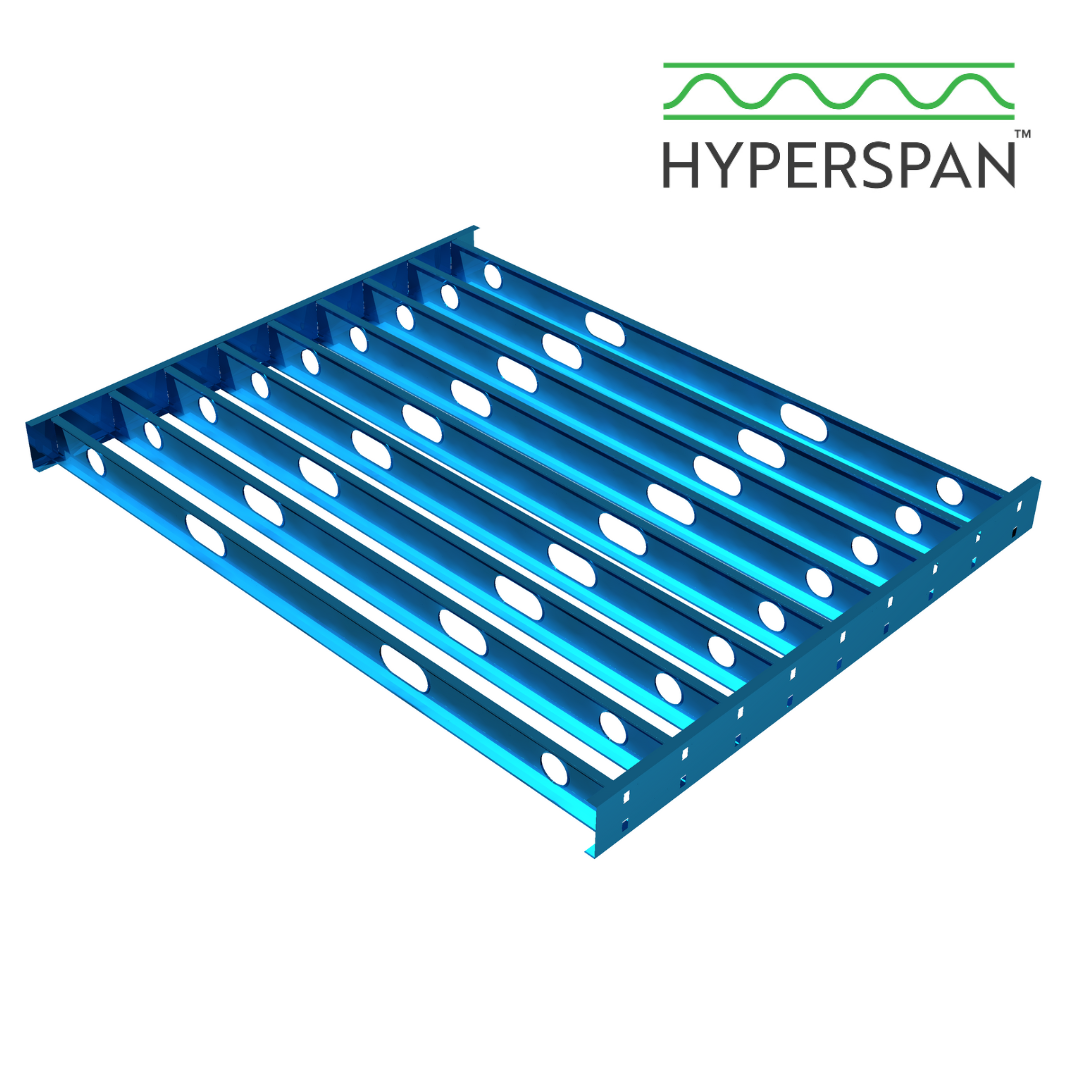

This year Dynamic Steel Frame introduced a new product to the light gauge steel industry. Hyperspan™ systems, a lighweight beam and flooring system developed to replace bulky structural steel. Hyperspan’s strength to weight ratio is second to none.

Hyperspan™ has become a popular framing choice on high volume townhouse sites. Many builders favour the efficiency an durability that technology guarantees.

townhouse development in Williamstown

“The feedback from our clients and installers has been extremely positive. The desired effect of increased on-site productivity, production speeds and reduced raw material usage has been achieved.”

Peter Blythe – Managing Director

Awards

In August managing director Peter Blythe and the team at Dynamic Steel Frame were recognised for our ongoing dedication and involvement in the light gauge steel manufacturing industry, at the 21st Victorian Manufacturing Hall of Fame Awards gala dinner.

Although Dynamic Steel Frame didn’t take out the first prize, being top three in the state amongst some pretty tough competition is something to be proud of.

“As a business owner, I’m incredibly proud of our team, who perform at the top of their game day in, day out. Watching their development is a constant source of pride and motivation for me, and it’s incredibly rewarding to see how far we have come in just 11 years”

Peter Blythe – Managing Director

Australia’s Favourite Renovation Show

Season 19 of Australia’s favourite renovation show, managing director Peter Blythe returned with TRUECORE® steel for this years retro renovations on Charming Street, Hampton.

Framing the studio and second storey additions with TRUECORE® steel and assisting contestants in utilising TRUECORE® steel throughout the building process.

This year was all about the curves. Curves over beds, curved air conditioning ductwork & coved ceilings. Creating these architectural additions in light gauge steel ensures that the lines are laser straight.

Trade Night

In September, Dynamic Steel Frame and Ideal Fasteners held a trade night in conjunction with TRUECORE® steel and NASH to introduce our latest technologies and innovations to the light gauge industry.

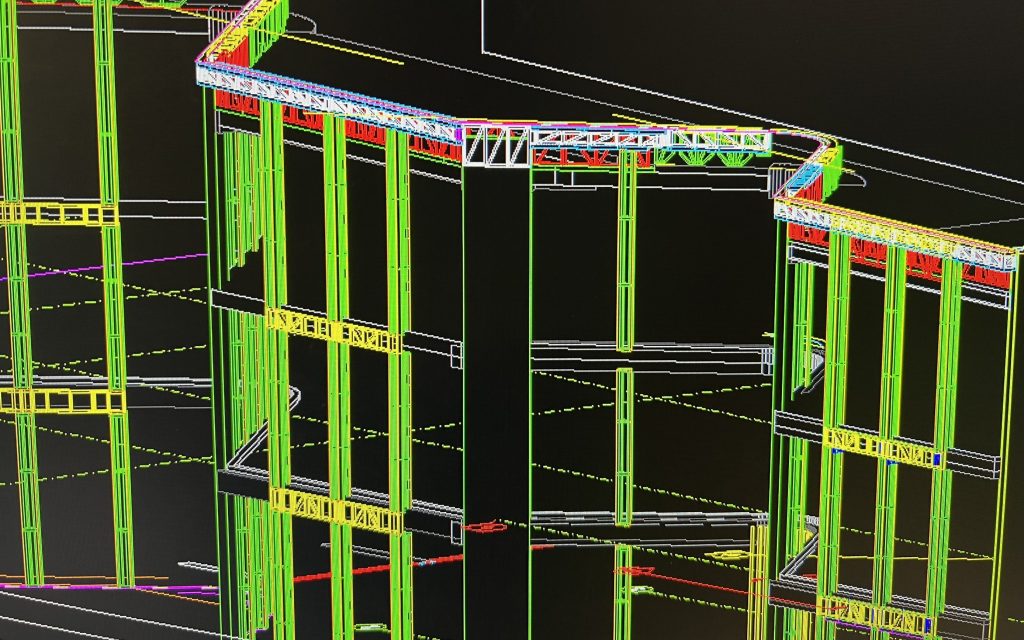

Showcasing our recently produced brick piers for a façade project with Cobild, BIM 3D models and our latest innovation Hyperspan™.

This night was a great opportunity for clients to see how utilising these new products in their next build can take their projects to the next level.

The team at Dynamic Steel Frame would like to thank all of our clients, friends and supporters for another fantastic year. We are excited to see what 2024 has install for us all, and cant wait for the incredible projects ahead.

Phone: 03 9701 7342

Email: sales@dynamicsteelframe.com.au