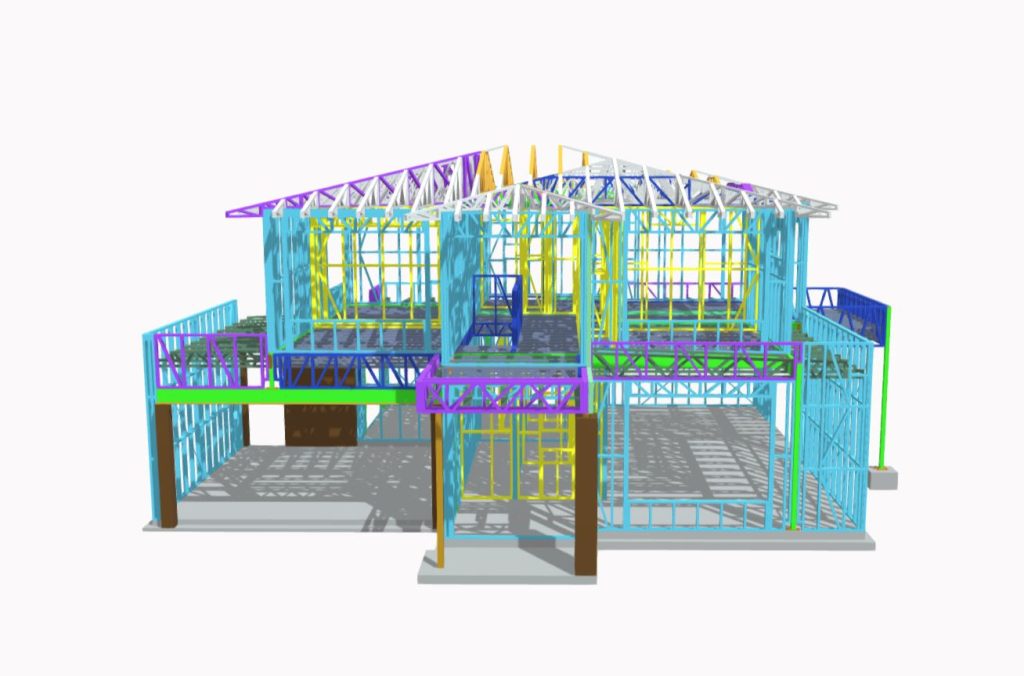

151 Chapel Road Keysborough consists of 56 townhouses and approximately 250,000 lineal meters of TRUECORE® light gauge steel framing.

Dynamic Steel Frame has been working on this recently completed townhouse development for a year now.

Our detailer Dai worked closely with the client to ensure the best outcome for this project. Below he speaks on some key points from this project.

Are there any houses that stood out to you? What is your favourite design features?

“Type F – unit 56 is a unique design. This particular type was one that was not repeated across the project. It’s got the largest amount of steelwork and the most complicated hip roof design compared to the rest. Saddle trusses were used to achieve the architectural intent, as well as making for easy installation onsite.“

Dai – Detailer

What was your favourite and least favourite part of the design?

“The design of a hip roof is always challenging. This can either be the most or lest favourite part of any design. It was a very challenging aspect of this project, but it was very satisfying to see it work so well onsite, once completed.“

Dai – Detailer

How did you manage the potential material delays and client expectations?

“We work very closely with our client’s in every project. However in a large townhouse project like this one it is essential! I had efficient discussions with the client’s draftsperson on the design intent which helped to minimise unnecessary rectification of frames onsite. Communication with the site manager assisted with anticipating the production workload along with site demand. With this we managed to deliver frames within the clients requested schedule.”

Dai- Detailer

Check out the below video’s of 151 chapel road and the progress of this site from flight one to flight six.

Lighter. Straighter. Better.

Lighter. Straighter. Better. Best.

Lighter. Straighter. Better..

Lighter. Straighter. Better.