In today’s fast-paced construction industry, innovation is a necessity rather than a bonus. Light gauge steel framing is emerging as a game-changer, revolutionising the construction process and how tradespeople approach their work on-site. Efficiency, precision, and sustainability are key factors for any trade, and light gauge steel framing addresses all three. Beyond enhancing structural integrity, it improves overall workflow and contributes to the long-term durability of projects, making it a crucial material in shaping the future of construction.

Speed and Efficiency

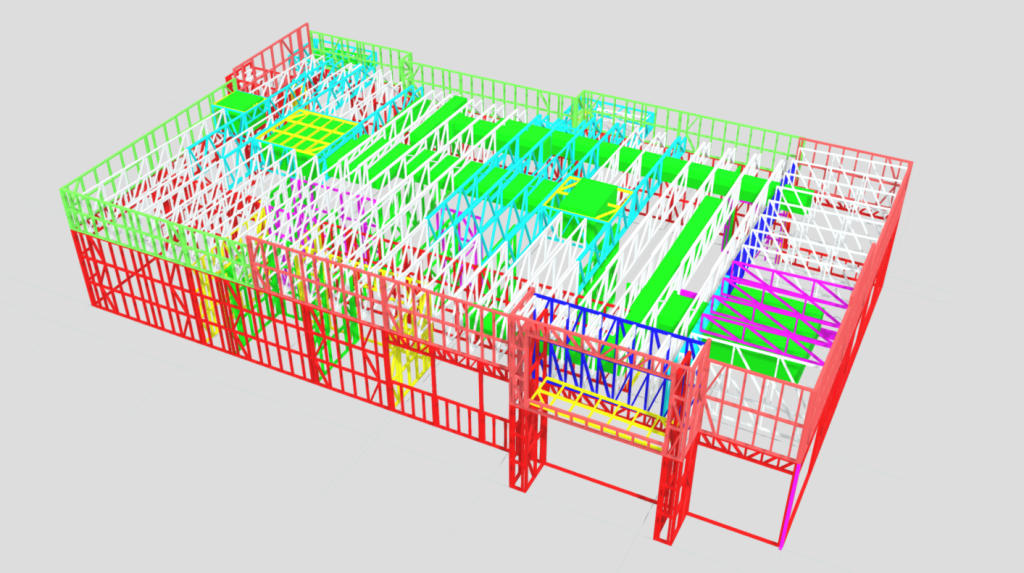

Light gauge steel framing uses advanced 3D (BIM) modelling technology for prefabrication. This approach means that frames arrive on-site ready for assembly, significantly reducing the time needed for installation. For trades, this results in shorter project timelines, fewer delays, and a smoother workflow.

By choosing TRUECORE® steel for your project, you’re not only investing in the strength and durability of Australian-made steel but also benefiting from its compatibility with advanced construction technologies like BIM. To ensure a seamless construction experience, it’s crucial to consider all services during the design process. Properly integrating elements like electrical, plumbing, and HVAC systems into the initial light gauge steel frame design significantly reduces the need for on-site modifications. This proactive approach streamlines the installation process and also minimises delays.

Ease of Handling and Installation

Despite its strength, light gauge steel is significantly lighter than timber, making it easier to transport and handle on-site. This reduces physical strain and simplifies the installation process, especially in complex builds with multiple stories. The result is a safer, more efficient working environment.

From a trade perspective, one of the biggest advantages of light gauge steel framing is the precision it offers. Prefabricated off-site, light gauge steel arrives at the job site ready for installation. The pre-engineered sections are cut to exact specifications, which reduces time spent on measurements and adjustments, accelerating the project’s completion. The precision of light gauge steel also means fewer errors, reducing the need for on-site modifications and minimising material waste. This boosts efficiency, allowing trades to move swiftly between tasks without compromising quality.

Durability in All Conditions

Another advantage of light gauge steel is its resistance to common issues that plague traditional materials. Unlike timber, steel doesn’t warp, rot, or twist, which is crucial when working on large-scale projects in varied weather conditions. This consistency ensures that the frame stays straight and true from the moment it’s installed and throughout the building’s lifetime.

The Future of Construction

Light gauge steel framing is proving to be an invaluable tool to forge the future of construction. With its precision, durability, and ease of use, light gauge steel is setting a new standard for building projects of all sizes. From reducing installation time to creating safer job sites, it’s clear not only is light gauge steel reshaping the way buildings are constructed but also how tradespeople approach their craft.

By embracing these advancements, the industry is moving towards a more efficient, sustainable, and innovative future – one frame at a time.

Phone: 03 9701 7342

Email: sales@dynamicsteelframe.com.au