In today’s construction landscape, flexibility and efficiency are crucial to meeting the evolving needs of diverse projects. Whether it’s a commercial development, residential building, or a large-scale townhouse developments, using steel in construction has become a preferred choice for its strength, durability, and sustainability. At Dynamic Steel Frame, we not only specialise in innovative light gauge steel framing but also offer in-house structural steel capabilities. Our structural steel solutions complement our light gauge steel solutions, providing a one-stop shop for your building requirements.

Why Structural Steel and Light Gauge Steel Work Together

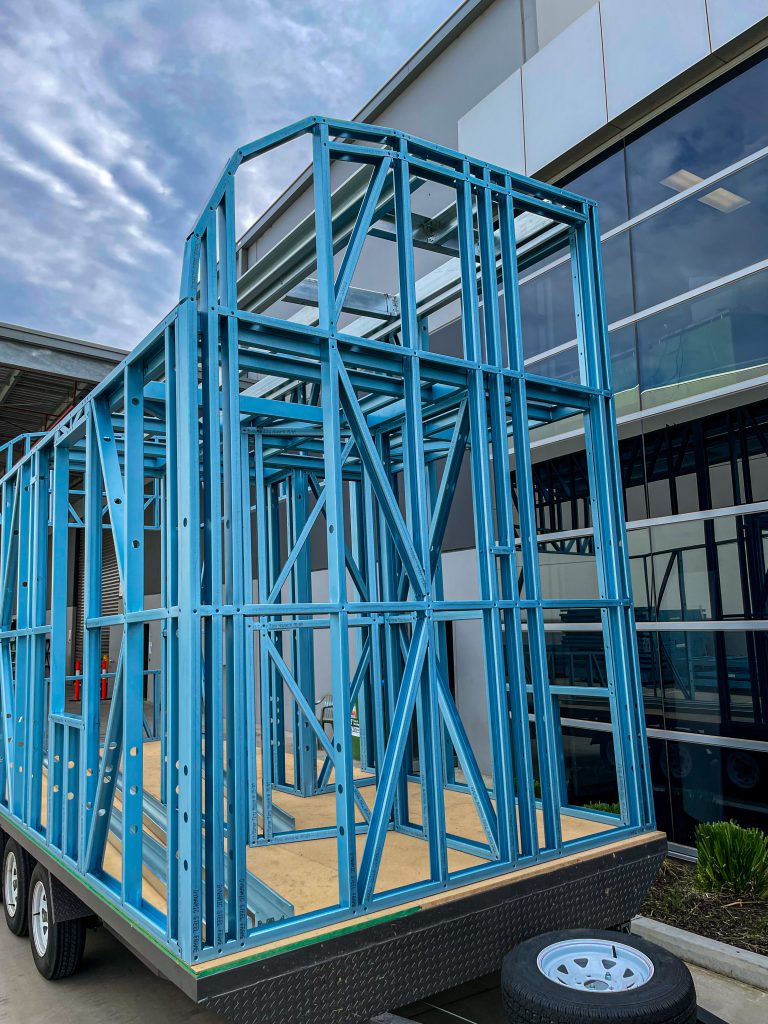

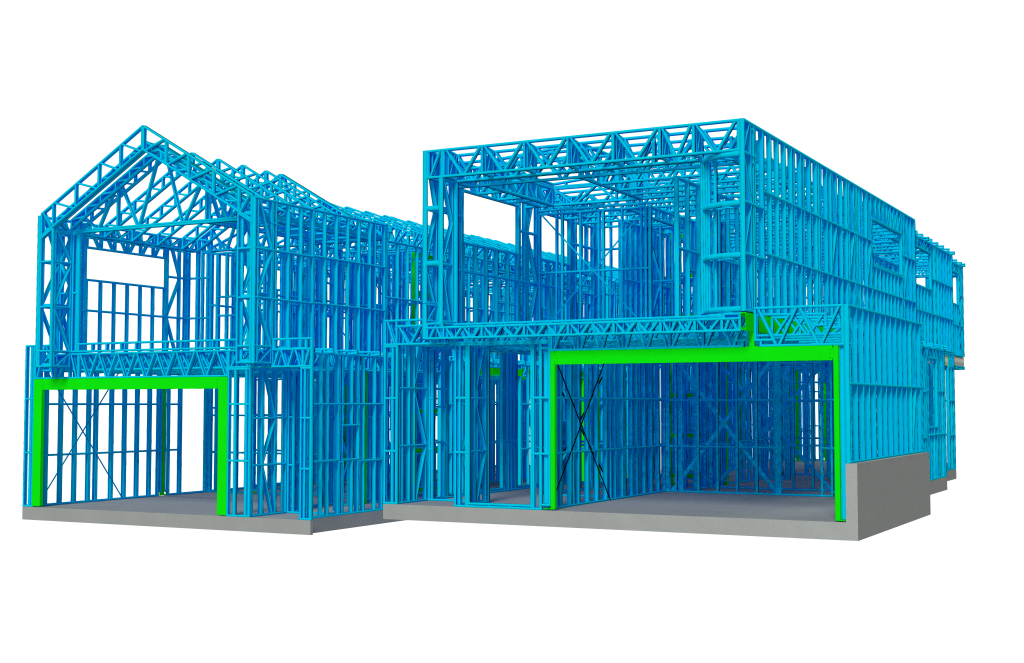

Light gauge steel is known for its versatility, being lighter, more precise, and easier to work with than traditional materials. It’s ideal for residential projects and certain commercial buildings due to its lightweight nature. Making it easier and quicker to install, reducing on-site labour and cutting down on construction time.

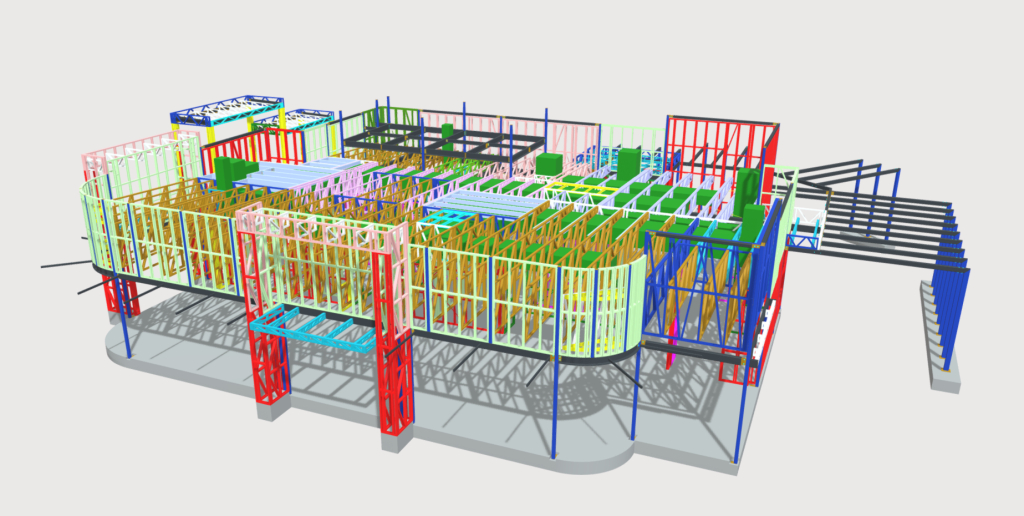

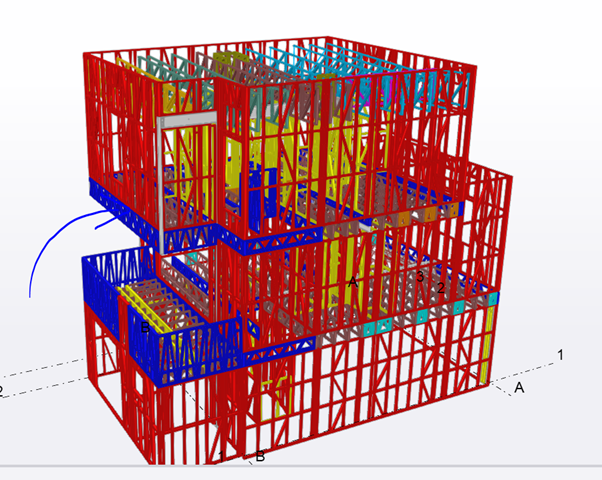

Structural steel is often required in our projects and forms an integral part of the stability of a building. By incorporating Dynamic Steel Frame’s structural steel solutions alongside our sturdy TRUECORE® framing, you’re ensuring unmatched durability and long-lasting strength. We prioritise compliance with Australian building codes, working exclusively with Australian engineers to ensure responsible design and adherence to regulations.

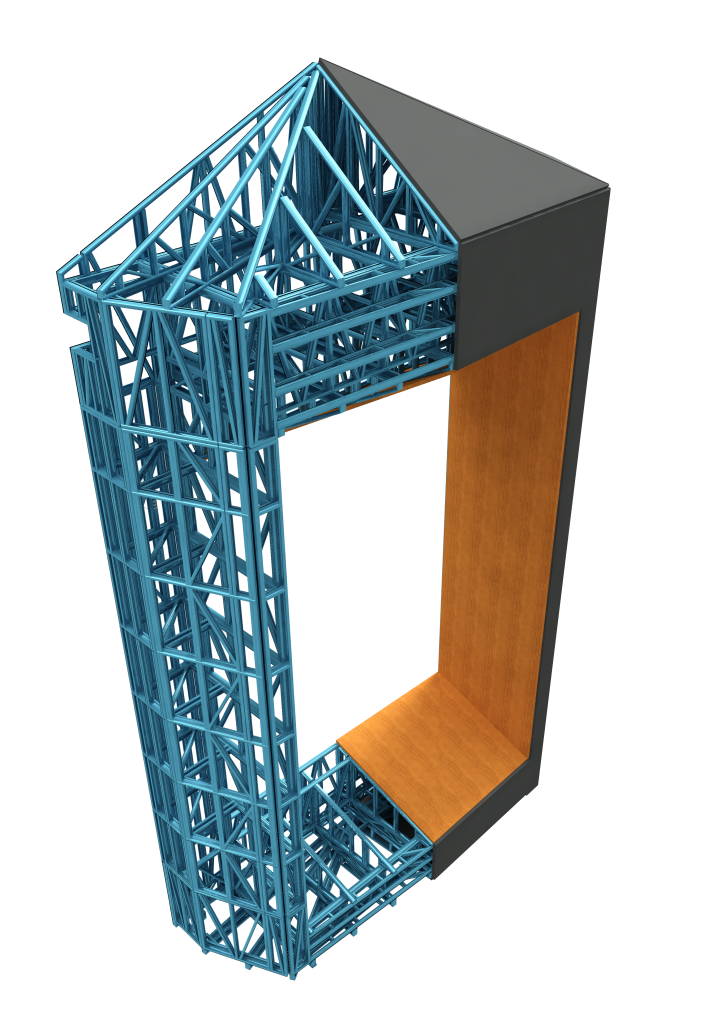

For projects requiring higher load-bearing capacity or for sections of the building that will carry more substantial weight such as roofs, heavy machinery platforms, or multistory commercial developments. Structural Steel steps in to provide the necessary reinforcement.

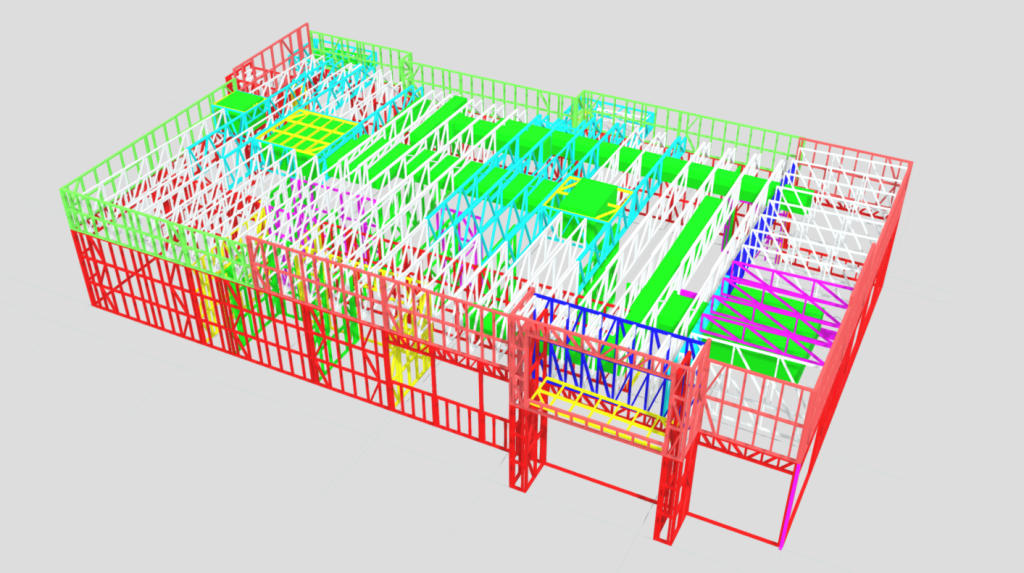

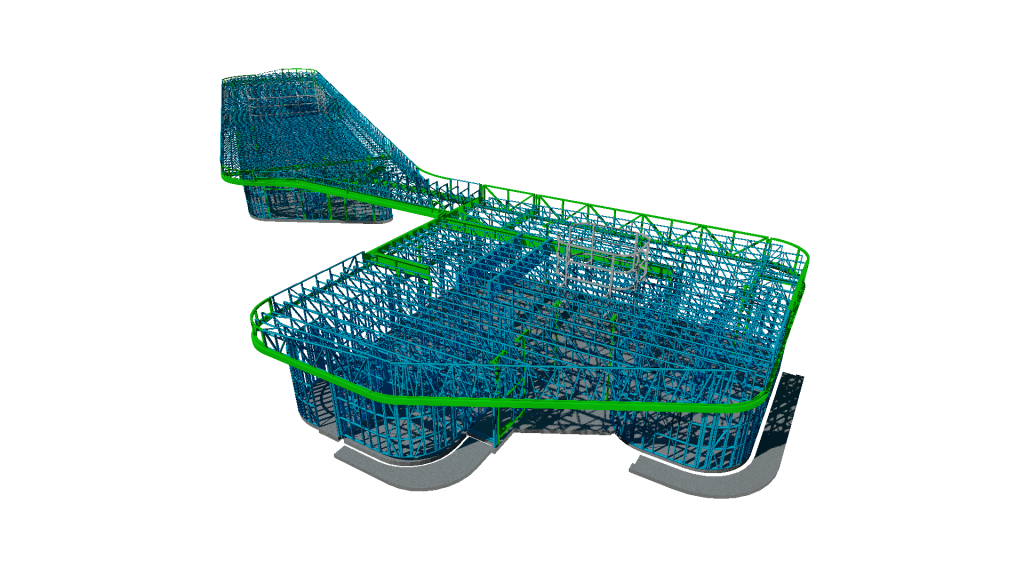

The combination of light gauge steel frames and structural steel creates a robust framework for buildings, offering the best of both worlds. While light gauge steel provides ease of installation and design flexibility, structural steel ensures the project can bear heavy loads and withstand rigorous structural demands. This collaborative approach results in an overall stronger, more efficient building solution.

Dynamic Steel Frame’s Structural Steel Capacity

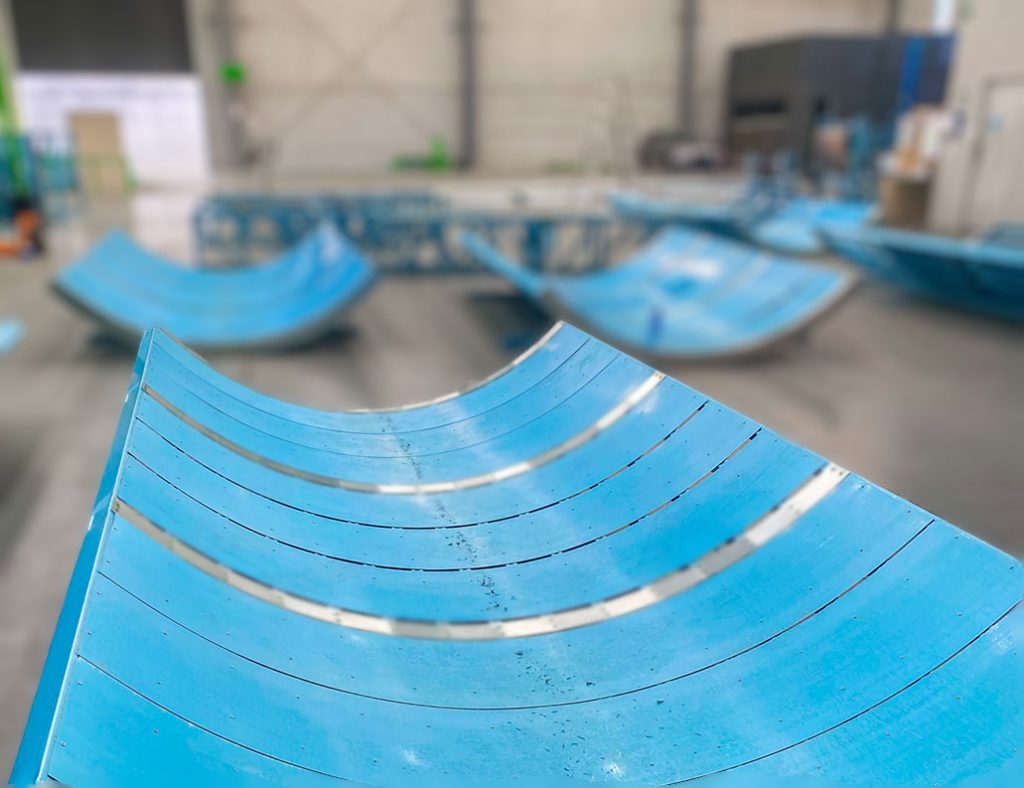

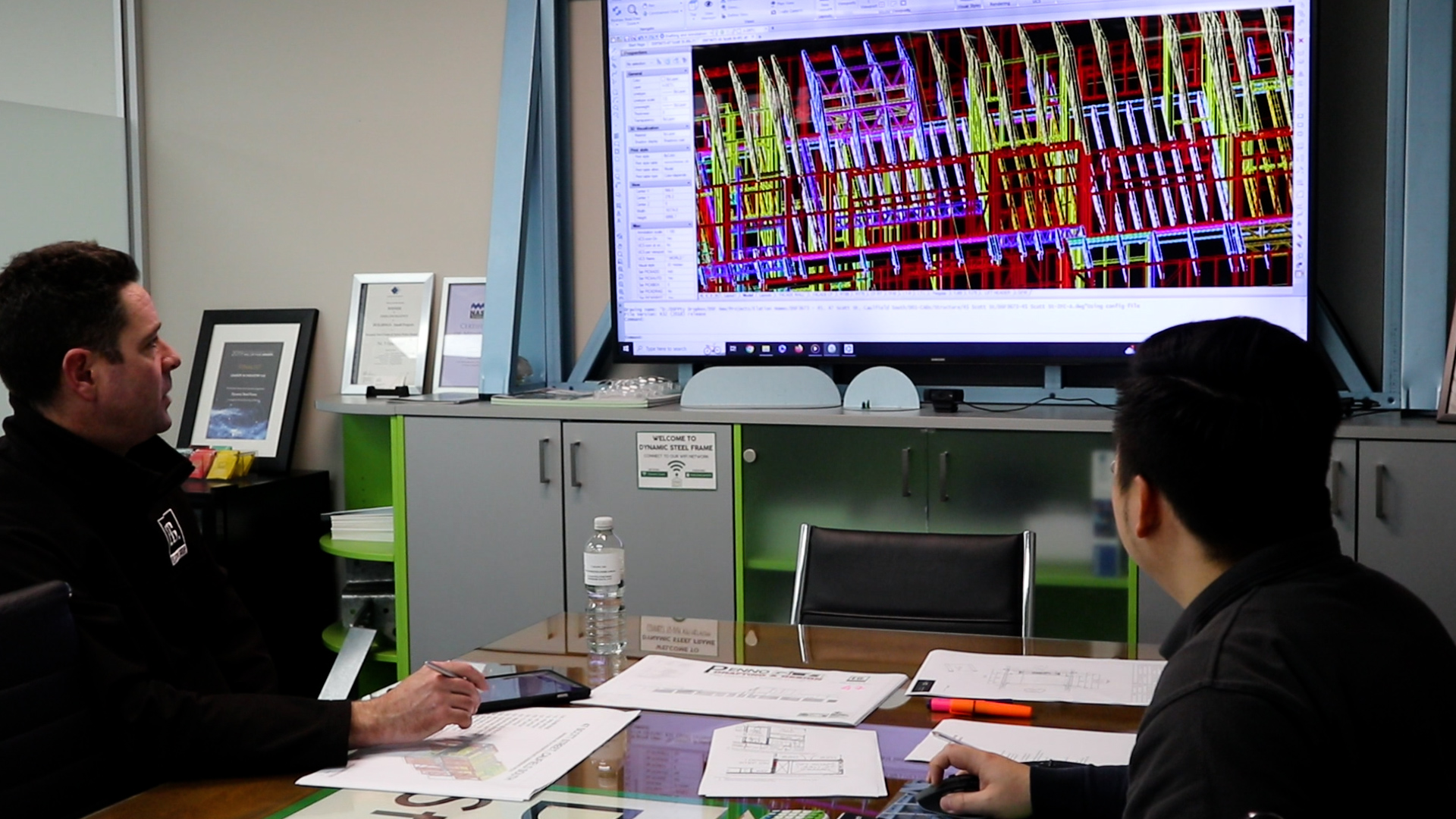

At Dynamic Steel Frame, we offer a comprehensive range of structural steel services tailored to meet the specific needs of your project. Our team has the expertise and equipment to fabricate custom structural steel solutions that meet the specific needs of your project. This allows us to deliver high-quality steel products that integrate seamlessly with our light gauge steel frames.

By offering both structural steel and light gauge steel under one roof, we provide significant advantages to our clients:

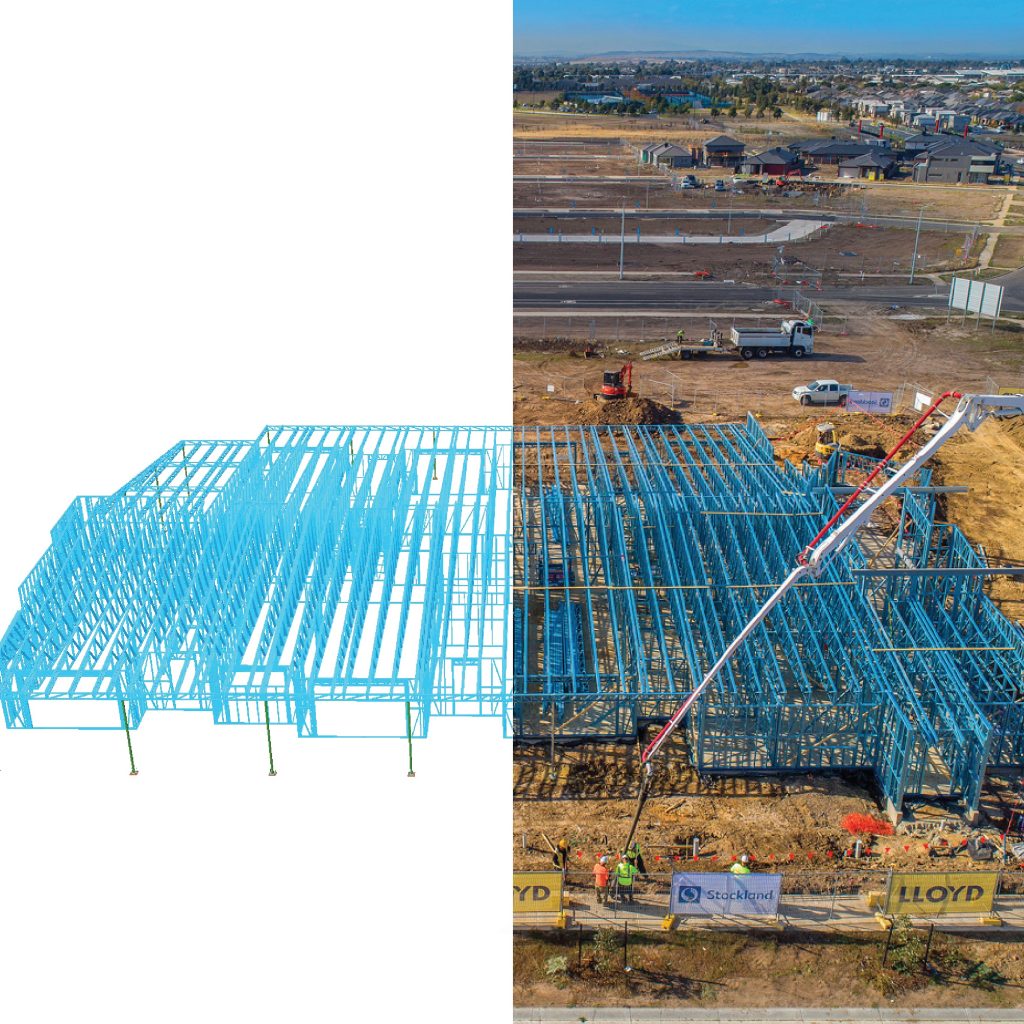

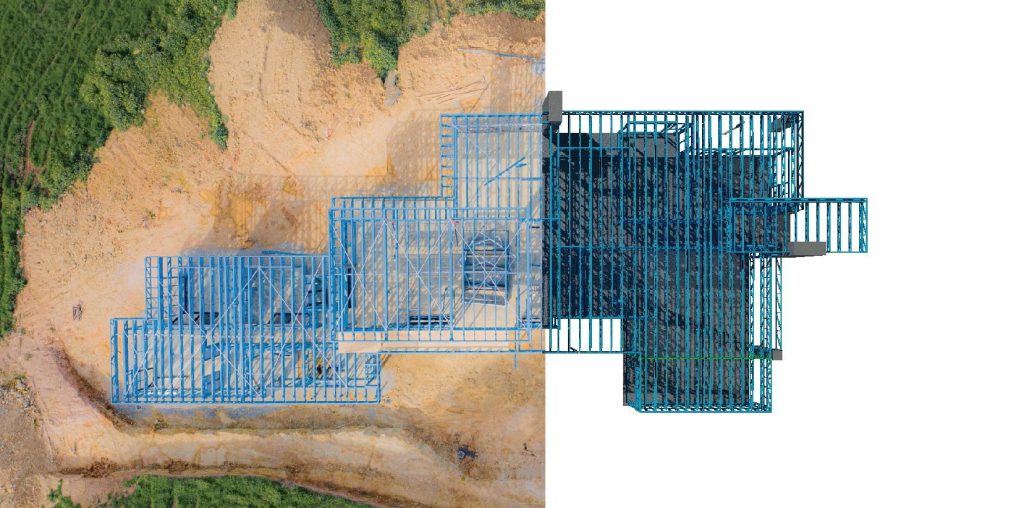

- Perfect integration: When Dynamic Steel Frame designs and supplies the steel to your project, you get perfect integration. Tolerances are tight and both heavy and light steel work together seamlessly, meaning fast erection times.

- Logistical support: When sourcing heavy and light steels from Dynamic Steel Frame, everything is ready to go at the right time, meaning hassle-free onsite coordination and trade progression.

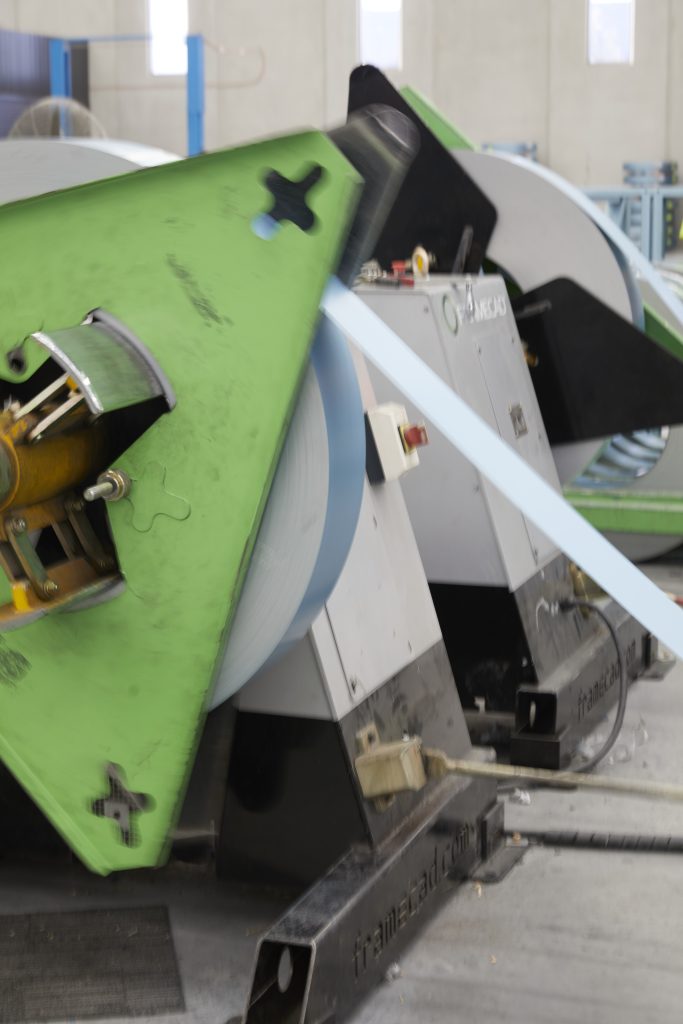

- In-House manufacturing: We design, model, shop draw and manufacture our structural steel in-house, not outsourced, so you can be assured of Australian-made quality throughout.

- Precision: Dynamic Steel Frame processes all our steel on CNC-controlled beam lines meaning penetrations are always precisely placed for speed and efficiency on site.

The Value of Comprehensive Solutions

By offering both light gauge steel framing and structural steel solutions, we ensure that your building project benefits from an integrated approach. This holistic solution enhances design flexibility, reduces construction time, and improves the overall performance of the building. Whether you need lightweight framing for a residential structure or strong structural supports for a large-scale commercial project, we can deliver tailored solutions to meet your specific building needs.

When light gauge steel and structural steel work in harmony, it maximises the performance of your building’s framework. Our ability to provide both solutions ensures that each section of the building is constructed with the optimal material for its specific demands. Making your building safer, more efficient, and ultimately, more cost-effective.

Conclusion

The integration of structural steel and light gauge steel is more than just a combination of materials. It’s about creating a building framework that delivers on strength, safety, and sustainability. With Dynamic Steel Frame’s comprehensive solutions, you’re not only receiving high-quality steel. But also the expertise to ensure that your building is designed and constructed to stand the test of time.

Whether you’re working on a new project or looking to integrate steel into an existing design, we’re here to help you achieve your goals with efficiency and precision. When you choose Dynamic Steel Frame, you’re choosing a partner committed to innovation and excellence.

Phone: 03 9701 7342

Email: sales@dynamicsteelframe.com.au