In the ever-evolving world of architecture, innovation and adaptability are key. Traditional materials like wood and concrete have long dominated the construction landscape, but architects and builders are increasingly turning to light gauge steel for its unique advantages. This shift is driven by light gauge steel’s ability to facilitate cutting-edge architectural designs that are not only structurally sound but also aesthetically stunning.

Flexibility in Design

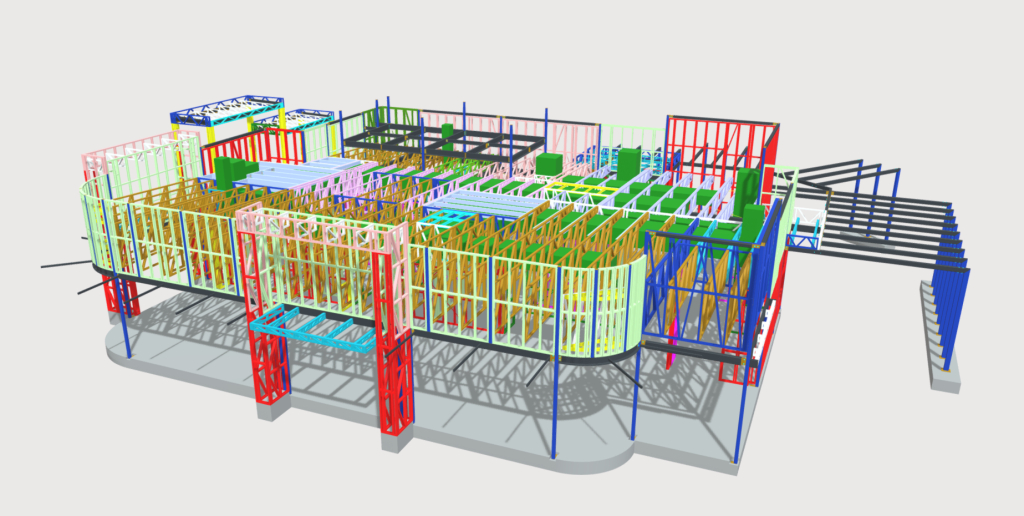

One of the most compelling reasons architects favor light gauge steel is its exceptional flexibility. Unlike traditional materials, light gauge steel can be easily shaped and customised to meet the specific needs of a project. This adaptability allows for the creation of complex geometries and intricate designs that would be challenging or impossible with other materials. Architects can push the boundaries of creativity, designing curved walls, unconventional angles, and expansive open spaces with ease.

Strength and Durability

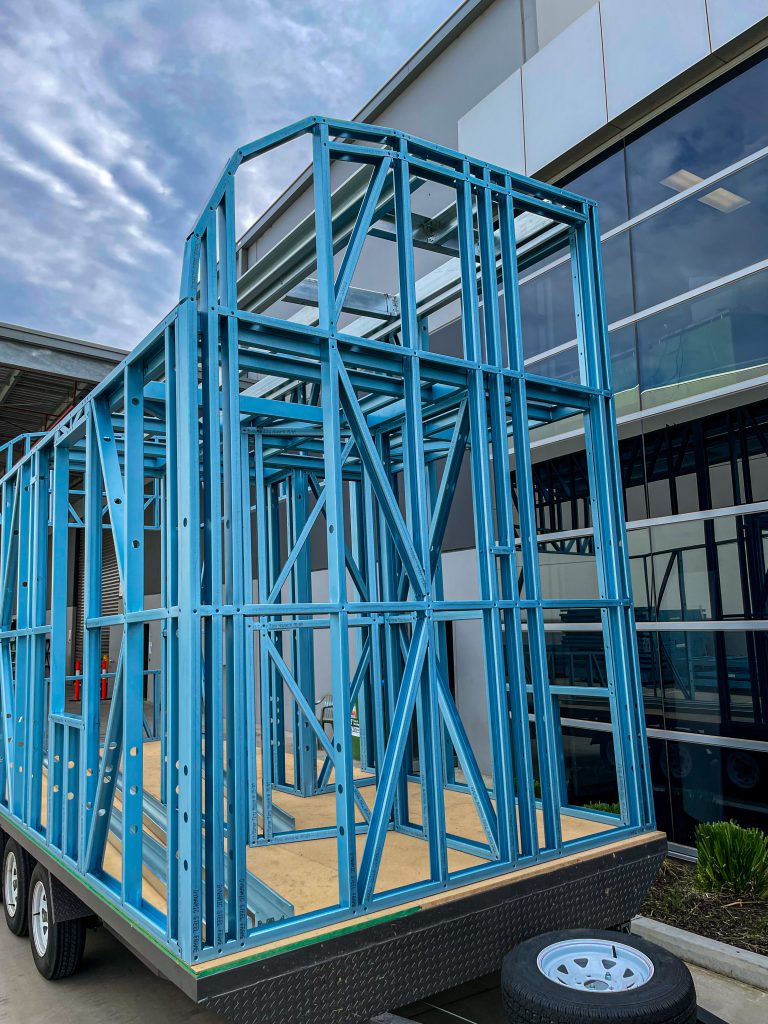

Despite its lightweight nature, light gauge steel is incredibly strong and durable. It offers a high strength-to-weight ratio, making it an ideal choice for structures that require both resilience and flexibility. This strength ensures that buildings can withstand environmental stresses, such as high winds and seismic activity, while maintaining their architectural integrity. For instance, the use of light gauge steel in high-rise buildings allows for the creation of slender, elegant structures without compromising on stability or safety.

Speed and Efficiency

The use of light gauge steel also significantly speeds up the construction process. Components are prefabricated off-site to precise specifications, which minimises on-site labor and reduces construction timelines. This efficiency is particularly beneficial for complex architectural designs that require meticulous assembly. Prefabrication ensures that each piece fits perfectly, reducing the likelihood of errors and ensuring a smoother construction process.

The integration of light gauge steel in architectural design represents a significant advancement in the construction industry. Its flexibility, strength, efficiency, and sustainability make it a preferred choice for innovative architectural projects. As architects continue to explore the possibilities of light gauge steel, we can expect to see even more groundbreaking designs that redefine the boundaries of modern construction.

Phone: 03 9701 7342

Email: sales@dynamicsteelframe.com.au