Australia’s favourite renovation show, The Block, is more than just high-pressure deadlines and creative reveals. Behind the cameras, it’s also a showcase of how modern construction methods and materials can push the industry forward. Contestants may be the faces of the show, but a network of suppliers and partners works tirelessly behind the scenes to ensure every build meets the highest standards — and is delivered on time.

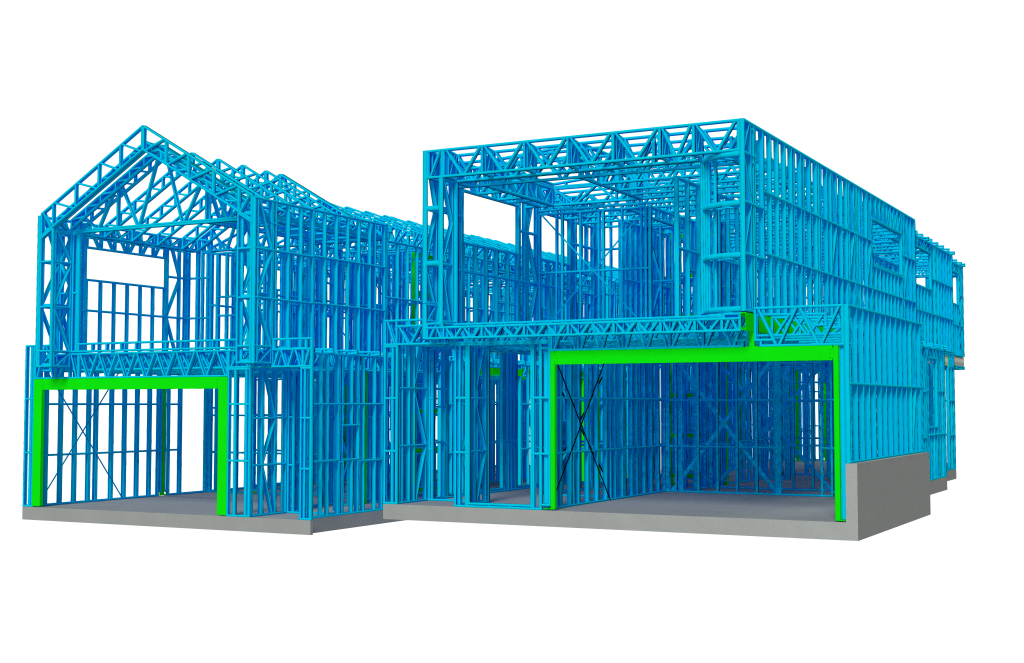

For several years, Dynamic Steel Frame (DSF) has proudly represented TRUECORE® steel as a trusted supplier on The Block. By providing prefabricated light gauge and structural steel frames, DSF helps contestants stay on top of the game with fast, accurate, and reliable framing solutions — a must when you’re building in front of a national audience with the clock ticking.

Why Steel is a Game-Changer on The Block

The challenge of The Block is unlike any traditional building project. Contestants face tight schedules, limited resources, and the added pressure of design scrutiny from judges and the public. For these reasons, the choice of building materials can make or break their success.

Prefabricated light gauge steel brings several advantages to the table:

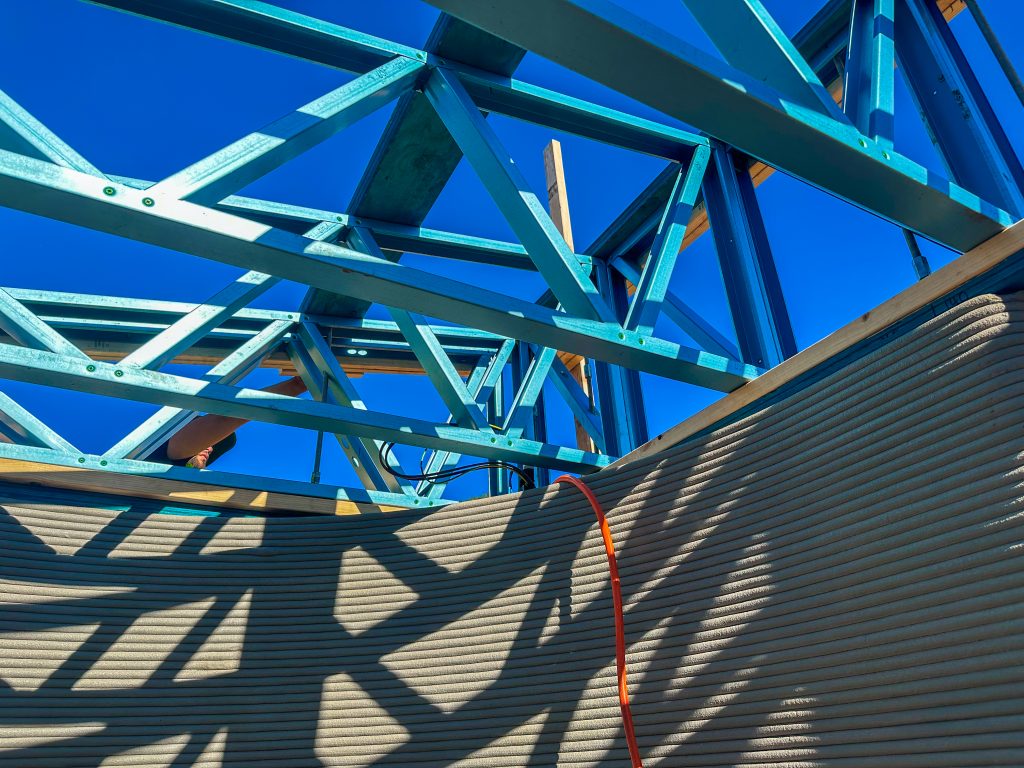

- Straight and true every time – Unlike timber, steel doesn’t twist, warp, or shrink, which means walls, ceilings, and finishes align with precision. Contestants save valuable time by avoiding costly rework.

- Non-combustible and durable – TRUECORE® steel offers long-term safety benefits, especially important for high-profile builds where quality cannot be compromised.

- Termite-proof and low maintenance – Contestants can rest easy knowing their frames won’t be compromised by pests or environmental changes.

- Speed and efficiency – With prefabricated frames delivered ready to install, contestants can move from slab to structure in record time.

In short, steel not only helps contestants survive the competition — it helps them excel.

Dynamic Steel Frame’s Role Behind the Scenes

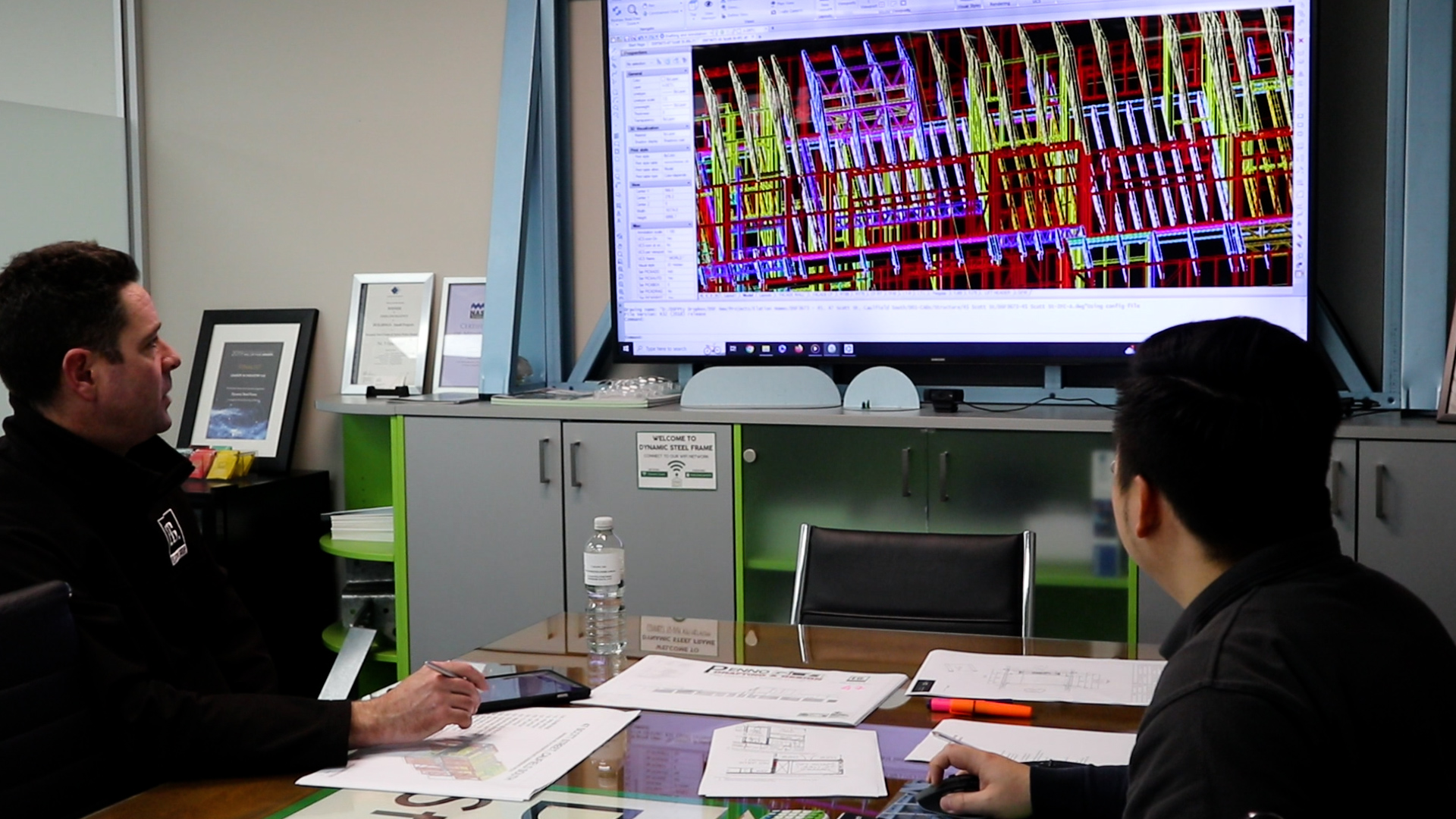

At DSF, our involvement in The Block goes far beyond delivering steel frames to site. Each season, we collaborate closely with the production team, contestants, and builders to ensure framing solutions meet both design intent and practical requirements.

Our role typically includes:

- Working with contestants and builders during the planning phase to finalise structural solutions.

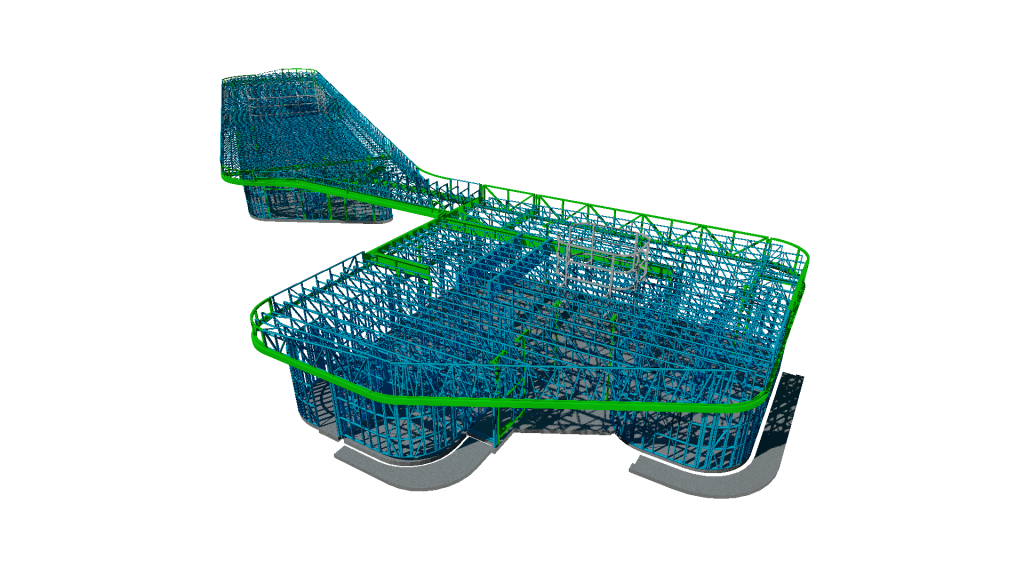

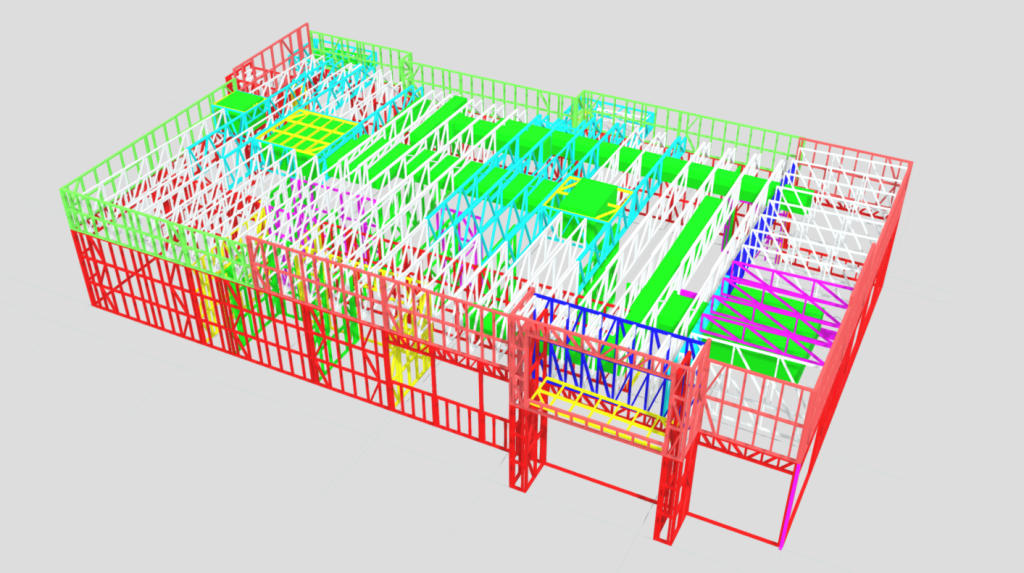

- Providing precision-detailed shop drawings and ensuring seamless BIM coordination.

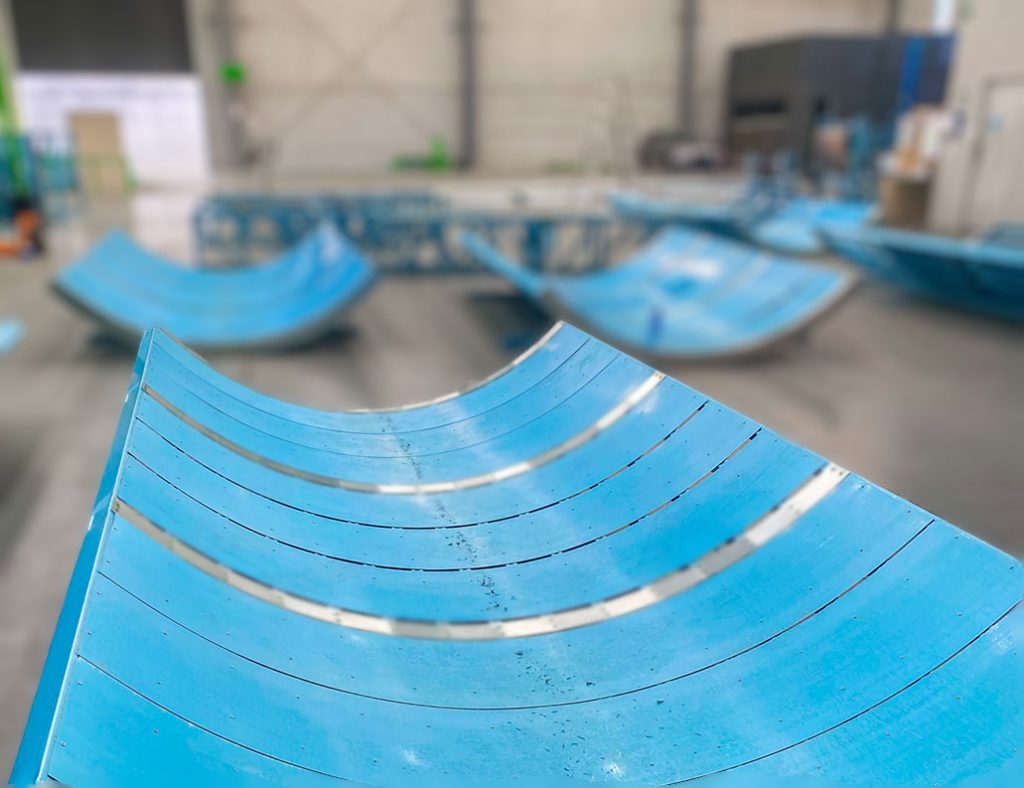

- Prefabricating light gauge steel frames and structural steel off-site for rapid installation.

- Supporting contestants with onsite guidance to keep builds running smoothly.

Our National Steel Frame and Truss Manager, Peter Blythe, also known as the “man of steel”, plays a hands-on role throughout the season. Alongside one of our expert detailers, Peter works directly with contestants and Nine in Six to ensure every frame is detailed to perfection and delivered exactly when required.

In 2024, we even took our commitment to the next level by operating a mobile rollforming unit (Factory in a Can) directly from Phillip Island. This innovation allowed steel frames to be rolled on-site, keeping production moving at the speed The Block demands.

We’ve also been part of educating contestants (and the wider audience) about the advantages of steel framing. From sustainability to precision, it’s a great opportunity to share knowledge while showing how steel is shaping the future of construction.

The 2025 Season at Daylesford

This year’s season of The Block was set against the picturesque backdrop of Daylesford. While the location may be serene, the builds were as challenging as ever — with contestants tasked to deliver unique, architecturally striking homes under pressure.

Once again, Dynamic Steel Frame partnered with TRUECORE® steel to provide the backbone of these builds. Our team supplied all light gauge steel and structural steel required for the houses, ensuring both speed and structural integrity.

But our involvement didn’t stop at the main builds. DSF also supplied steel for additional on-site framing needs, including specialised areas like the interview room. This highlights not only the adaptability of light gauge steel but also DSF’s ability to scale solutions for both primary structures and supporting elements.

Building Smarter: Lighter. Straighter. Better.

At the heart of DSF’s contribution to The Block is our belief in building smarter. TRUECORE® light gauge steel embodies this philosophy:

- Lighter – Easier to transport, handle, and install on busy construction sites.

- Straighter – Always dimensionally accurate, delivering the perfect base for interior finishes.

- Better – A future-ready material that offers strength, sustainability, and safety.

When paired with DSF’s advanced prefabrication methods and close collaboration with builders, these qualities translate into builds that are faster, cleaner, and more precise.

Why This Matters Beyond the Show

While The Block is a television production, the lessons it highlights are real. The construction industry is facing increasing demand for faster delivery, better sustainability outcomes, and long-term durability.

What DSF demonstrates on The Block is how prefabricated steel framing can meet these challenges head-on. By showing millions of Australians what’s possible with steel, we’re helping to shift mindsets from “traditional” to “smarter” ways of building.

Whether it’s a contestant racing against the clock or a family building their forever home, the benefits are the same: safer, stronger, straighter frames that are built to last.

Conclusion

Behind the glitz and drama of The Block, there’s a serious story of innovation, collaboration, and industry change. By representing TRUECORE® steel and supplying both light gauge and structural steel, Dynamic Steel Frame plays a vital role in helping contestants deliver homes that aren’t just TV-ready, but structurally future-ready too.

From operating a mobile rollformer to delivering complete framing packages, DSF continues to show why we are Victoria’s leading manufacturer of steel frames. And as each season of The Block proves, when you build with steel, you’re building Lighter. Straighter. Better.

Phone: 03 9701 7342

Email: sales@dynamicsteelframe.com.au