As we wrap up another incredible year, Dynamic Steel Frame is proud to reflect on the milestones, achievements, and innovations that made 2024 so memorable.

Projects

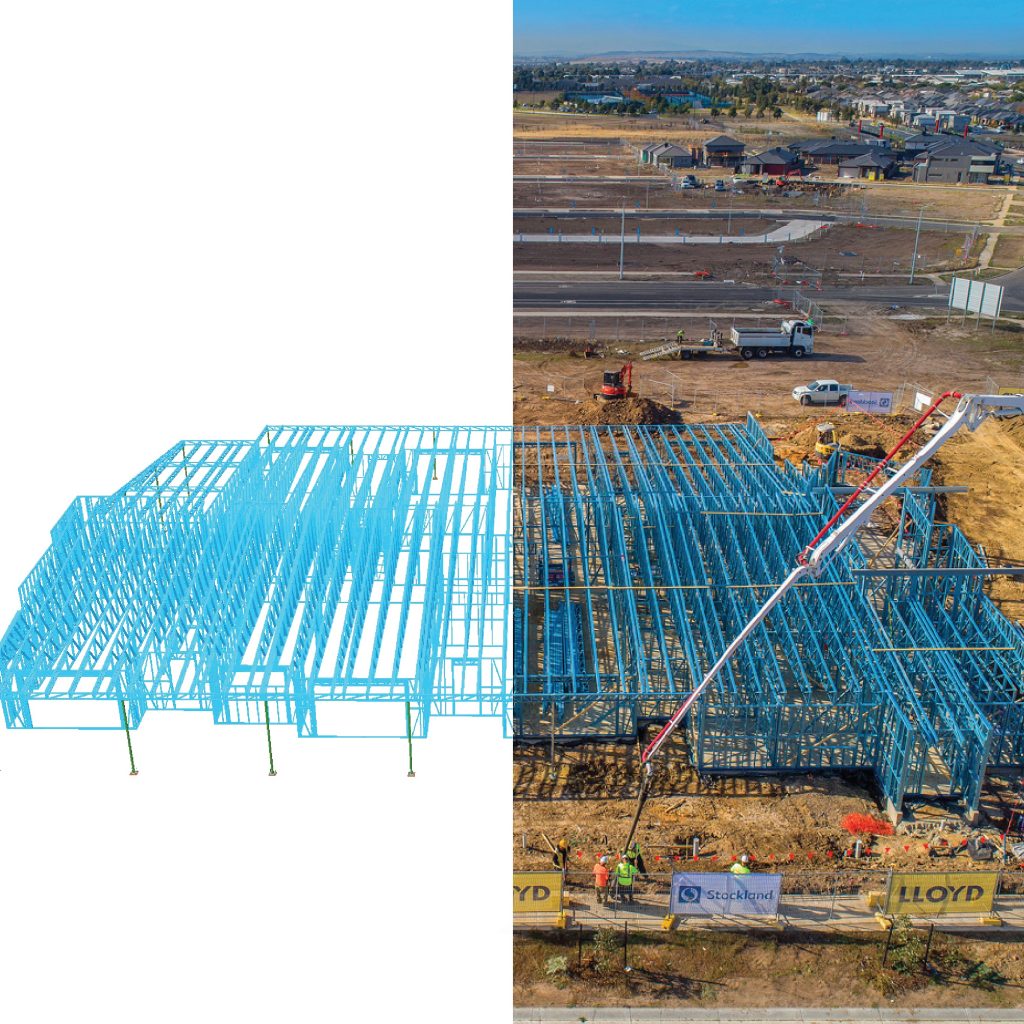

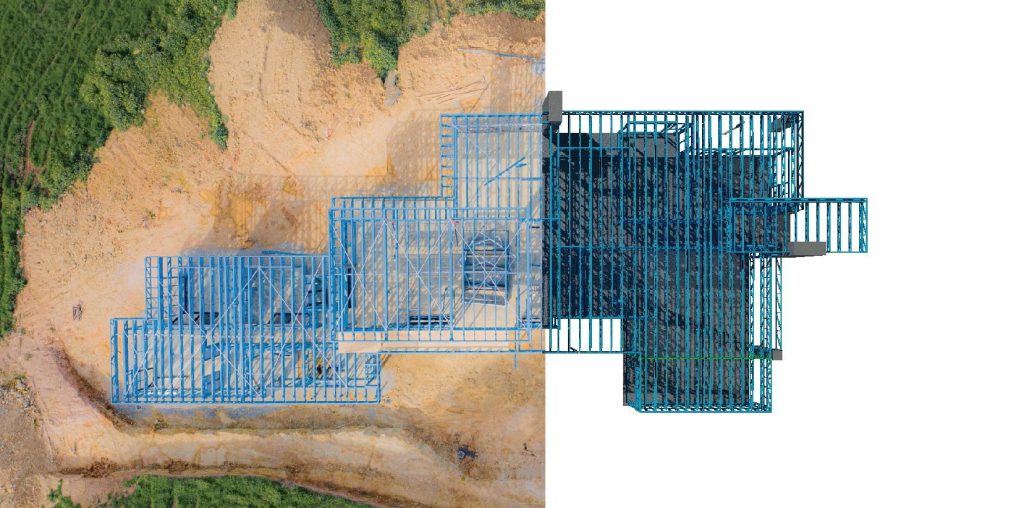

This year, we delivered on a wide range of projects—from residential builds to large-scale commercial developments. Each project showcased our dedication to precision, quality, and efficiency.

Some of the projects completed include:

- Victoria Road, Ventnor – Residential Development

- Cropping Street, Clyde North – 21 Townhouse Development

- Nova Circuit, Bundoora – 54 Townhouse Development

- Milton Parade, Glen Iris – 5 Townhouse Development

Innovative Solutions

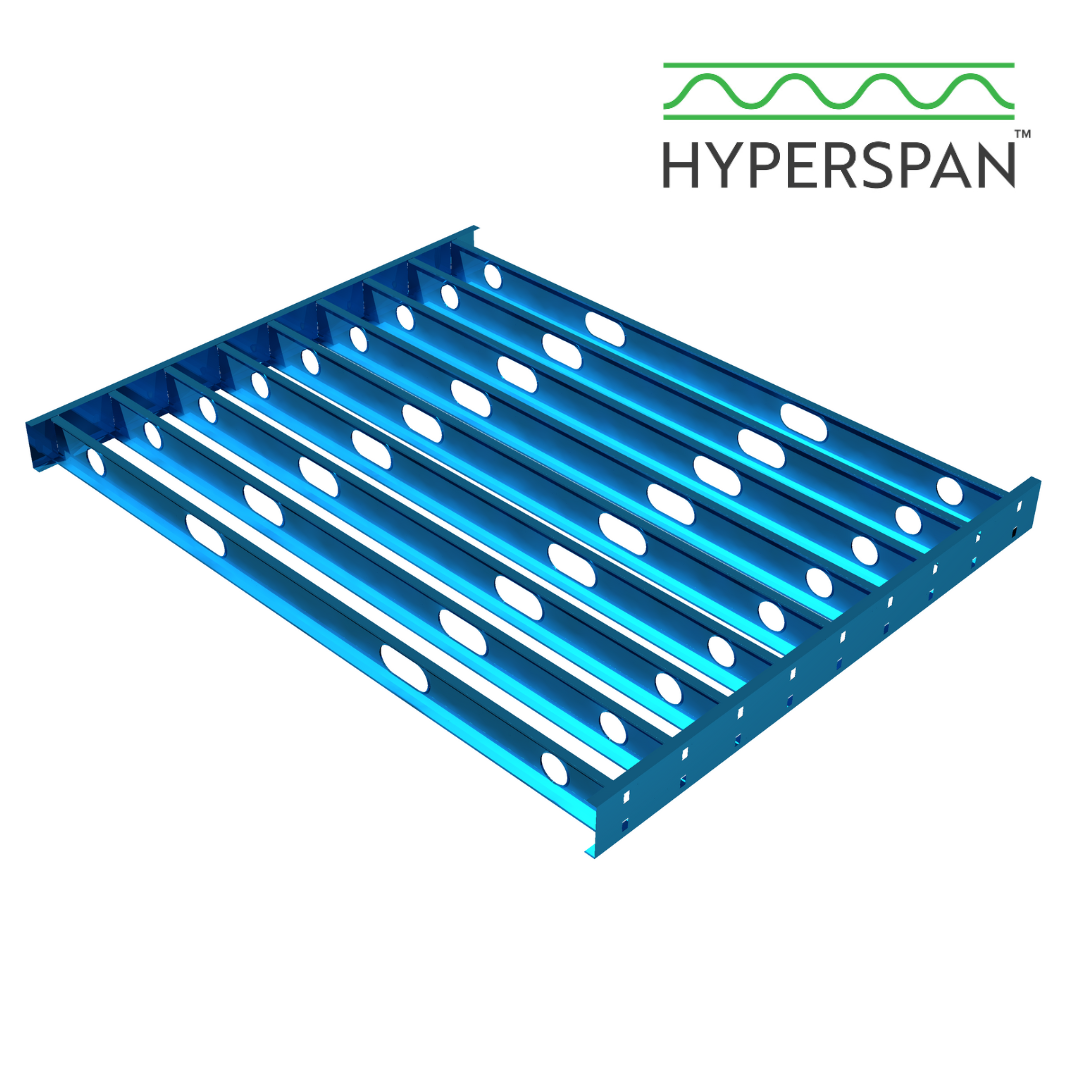

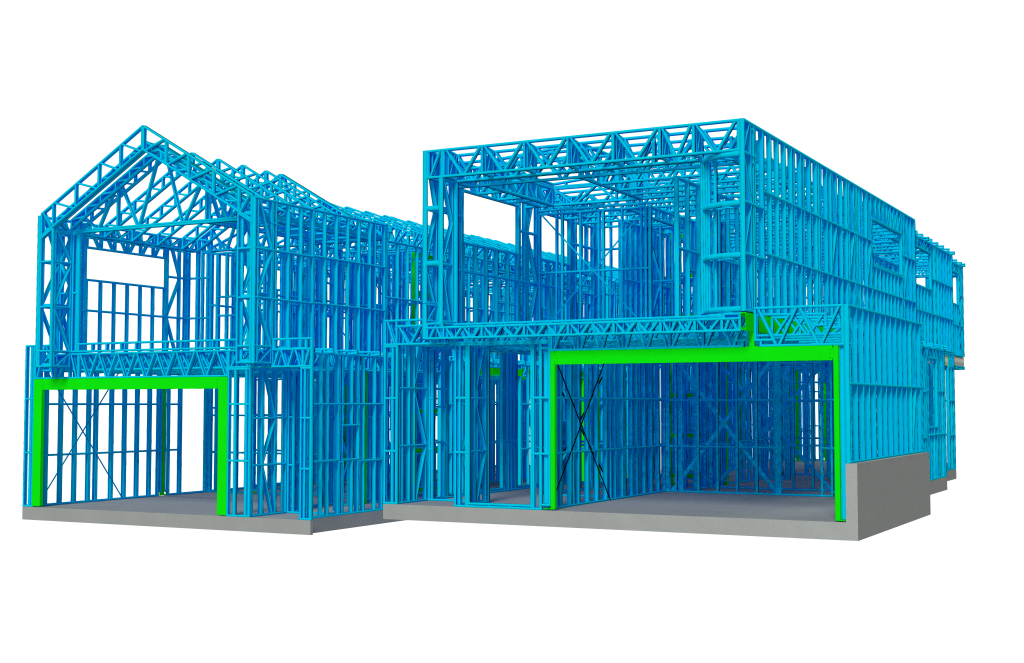

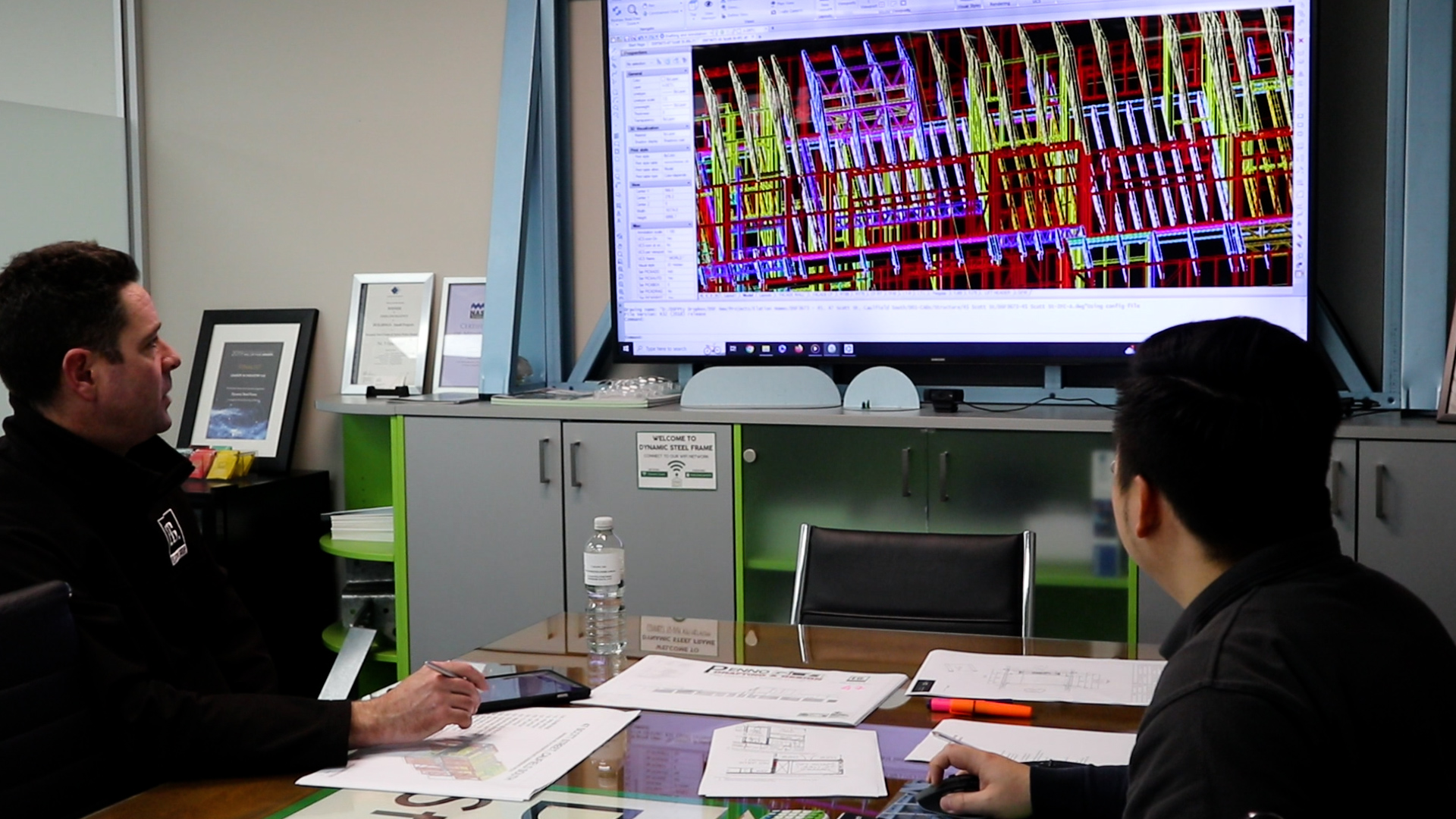

2024 has been a pivotal year for Dynamic Steel Frame as we solidified our reputation for delivering integrated solutions that streamline construction processes. By combining light gauge steel and structural steel expertise, we’ve established ourselves as a true one-stop shop for builders and developers.

Our ability to integrate these two critical components offers unparalleled efficiency and precision. With both systems designed, engineered, and fabricated in-house, we ensure seamless compatibility between the light gauge steel framing and the structural steel elements, such as beams, columns, and plant platforms. This approach reduces complexity, minimizes delays, and results in a stronger, more cohesive framework.

One standout example from this year is the use of our structural steel in lift shafts and plant platforms, which work seamlessly with our light gauge steel framing. This level of integration allows us to tackle complex designs and multi-story builds with ease, providing builders with confidence in both the structural integrity and efficiency of the finished product.

Dynamic Steel Frame’s continued investment in cutting-edge technology and design innovations allows us to meet the evolving demands of modern construction. By providing an all-in-one solution, we are not only simplifying the building process but also delivering a superior product that sets the standard for strength, durability, and versatility.

Collaborations and Partnerships

We’re incredibly grateful for the opportunities we’ve had this year to collaborate with an outstanding network of builders, architects, and suppliers. These partnerships have been the cornerstone of our ability to deliver tailored solutions that meet the evolving needs of our clients. Whether it’s on-site efficiency, innovative design integration, or overcoming unique construction challenges, these relationships have enabled us to achieve more together.

Awards

In November, Dynamic Steel Frame won the ASI Steel Excellence Award for Innovative Cold-Formed Steel! This recognition highlights our dedication to pushing the boundaries of steel construction. The award-winning project, KFC Dandenong, showcased our ability to integrate light gauge and structural steel seamlessly, creating an efficient, durable, and sustainable solution.

Australia’s Favourite Renovation Show

Season 20 of Australia’s favourite renovation show, National Steel Frame & Truss Manager Peter Blythe returned with TRUECORE® steel contributing to this year’s breathtaking builds at Phillip Island.

This season, we showcased the capabilities of our innovative Factory in a Can technology, which allowed us to produce steel frames directly on-site. By streamlining production and reducing transportation needs, Factory In a Can ensured efficiency, precision, and seamless integration with the fast-paced demands of the show.

It was an incredible opportunity to demonstrate the versatility and innovation of light gauge steel in action!

Our Incredible Team

None of this would be possible without the hard work and dedication of our talented team. Their skill, hard work, and commitment to quality ensure we consistently deliver exceptional results, driving our achievements year after year.

Looking Ahead to 2025

As we move into 2025, we remain committed to pushing boundaries and delivering exceptional results for every client. We look forward to continuing our mission of building lighter, straighter, and better with our trusted partners and team.

Thank you to everyone who has been a part of our journey this year. Here’s to an exciting and successful 2025!

Phone: 03 9701 7342

Email: sales@dynamicsteelframe.com.au